Recently, Prof. Zhaoping Lu’s group, from the Beijing Advanced Innovation Center for Materials Genome Engineering, State Key Laboratory for Advanced Metals and Materials at USTB, solved the problem of oxygen brittleness of refractory high entropy alloys(RHEAs) through grain boundary (GB)engineering. This research was published in the Materials Today, with the title of " Solving oxygen embrittlement of refractory high-entropy alloy via grain boundary engineering ".

Refractory high entropy alloys, particularly NbMoTaW RHEAs, have exhibited great potential to be utilized as high-temperature structural materials due to their superior phase stability and strength at elevated temperatures. However, they usually fractured intergranular without obvious plasticity at ambient temperature, resulting in poor processabilityduring rolling and forging.Thus, it is imperative to unveil the underlying mechanism of the room-temperature brittleness in the NbMoTaW type RHEAs so that the aforementioned challenge can be properly addressed.

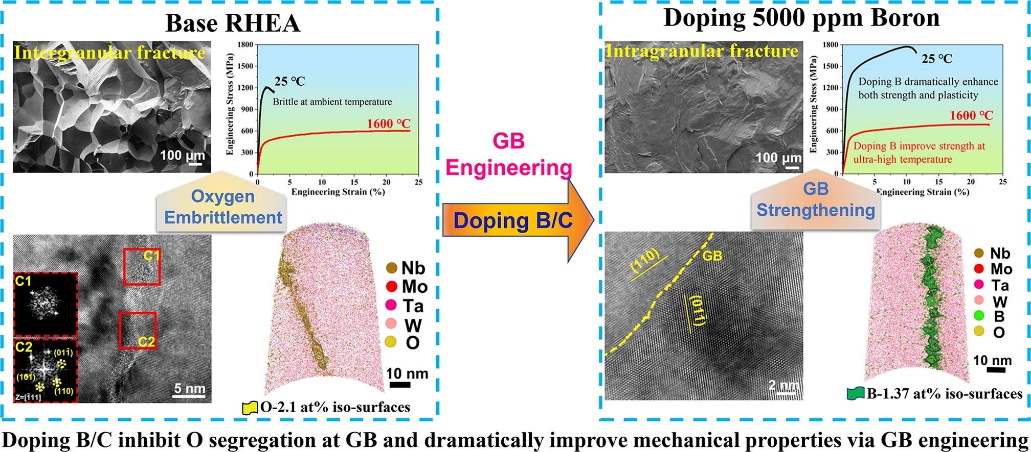

To addressthesechallenges, we scrutinized the deformation and fracture mechanism of NbMoTaW RHEAs. It was revealedthe origin of the room-temperature brittleness of the as-cast NbMoTaW RHEA originates from the GB segregation of theoxygen contaminant which weakens GB cohesion, due to the inevitable oxygen contamination during fabrication. We then attempted to solve this critical issue via doping of small elements such as B and C which preferentially replace oxygen at GBs (i.e., clean the GBs) and promote stronger electronic interaction with the host metals. As a result, the GB brittleness was effectively alleviated, and the fracture mode changed from intergranular to transgranular, giving rise to substantially enhanced mechanical properties at ambient temperature. Specifically, the RHEA doped with 5000 ppm B displayed large plasticity of >10%, along with high strengthof >1750 MPa, which is superior to the un-doped NbMoTaW RHEA. The doped RHEA also shows a strength of around 700 MPa at 1600℃, which is ~200 MPa higher than that of the un-doped NbMoTaW RHEA.

This research not only shed light on the understanding of the embrittlementmechanism of RHEAs in general, but also offer a useful route for ductilization of brittle HEAs.