The project of “7050 Aluminum Alloy Alloy Recycling at Pilot Scale”, developed by ProfessorZhangShengen , has been passed the acceptance by Boeing Company on June 17th, 2020. Webex was used for the online acceptance meeting. Professor Shengen Zhang’s team made a summary report of the project, and relevant staff from Boeing China Research and Technology Department attended the acceptance meeting.

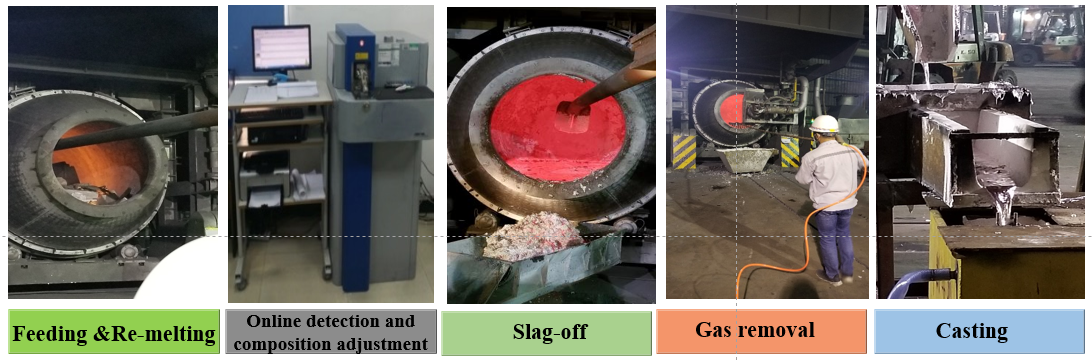

This project developed technologies for recycling aero aluminum alloy on 5.0 tons scale experiment.Using 7050 aero aluminum alloy machined aluminum chip as raw material, the tonnage recycling of 7050 aero aluminum alloy has been achievedafter pretreatment, melting, composition online control, impurity removal, gas removal, casting, etc..The ingots meet standard requirementsof American Society for Testing Materials (in briefly ASTM). The successful acceptance of this project has laid an industrial foundation for the grade-maintaining recycling of aero aluminum alloy.

Figure 1.Process of recycling 7050 aluminum alloy

Figure 2. Casting ingots of recycling 7050 aluminum at tons level

After the report,Professor Zhang prospected the industrialization of aero aluminum alloy grade-maintaining recycling. Industrial scale production (50-100tons recycling test) should be carried out in order to verify the stability and reliability of the recycling technology and developed approach. In addition, standards and policies should be improved and promoted to facilitate the application of recycled aviation aluminum alloy.

Boeing company fully affirmed the achievements of the project and highly appreciated the contribution of Professor Zhang’s team in the field of aero aluminum alloyrecycling. They expressed the willing of further cooperation to promote the industrialization application.