Parameters:

Applications

1. Room temperature X-ray diffraction

Scan angle (2θ): 10~150°

Scan speed: 10 ~15° / min

Powder sample: 200 ~ 300 mesh, 1-2 g

Block sample: Flat surface,residual stress free;

Maximum size of sample surface: 20 mm×20 mm

2. High temperature in-situ X-ray diffraction

Temperature range: R.T.~1200 ℃

Heating rate: 10° / min

Scan speed: 10~15° / min

Powder sample: 200 ~ 300 mesh, not reactive with metal Pt

Metal sheet sample: maximum 22 mm× 11 mm× 0.5 mm

3. SAXS:

Angle: 0.5 ~ 5°

Angular resolution: 0.1° (2θ)

Sample size: 4 mm × 32 mm × 2 mm

Features

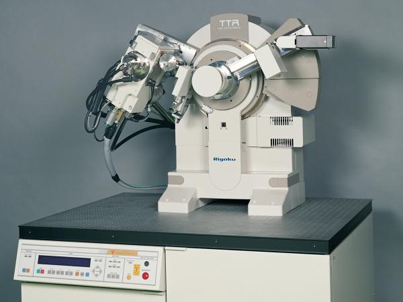

XRD (X-ray diffraction) is an essential method for materials characterization. TTR Ⅲ multipurpose X-ray diffractometer, which is made by Rigaku Corporation, proves powder diffraction, high-temperature XRD and thin film diffraction and small angle X-ray scattering (SAXS). It can be used for composition identification, crystal orientation, powder crystallography, qualitative analysis and quantitative analysis.

Parameters

1. X-ray generator

Maximum rated power: 18 KW

Tube voltage: 20 - 60 kV

Tube current: 10 - 300 mA

Target material: Cu

Focal spot size: 0.5 mm × 10 mm

2. Goniometer

Radius: 285 mm

2θ: -10 ~ 154°

Minimum step: 1 / 10000

Scan speed (2θ): 0.0002~100° / minute

Monochromator: graphite crystal monochromator

3. Counter

Scintillation counter

Linear count: 700 thousand cps

Maximum count: 1 million cps

Location: Room 183, main building

Contact: Shuying Zhen